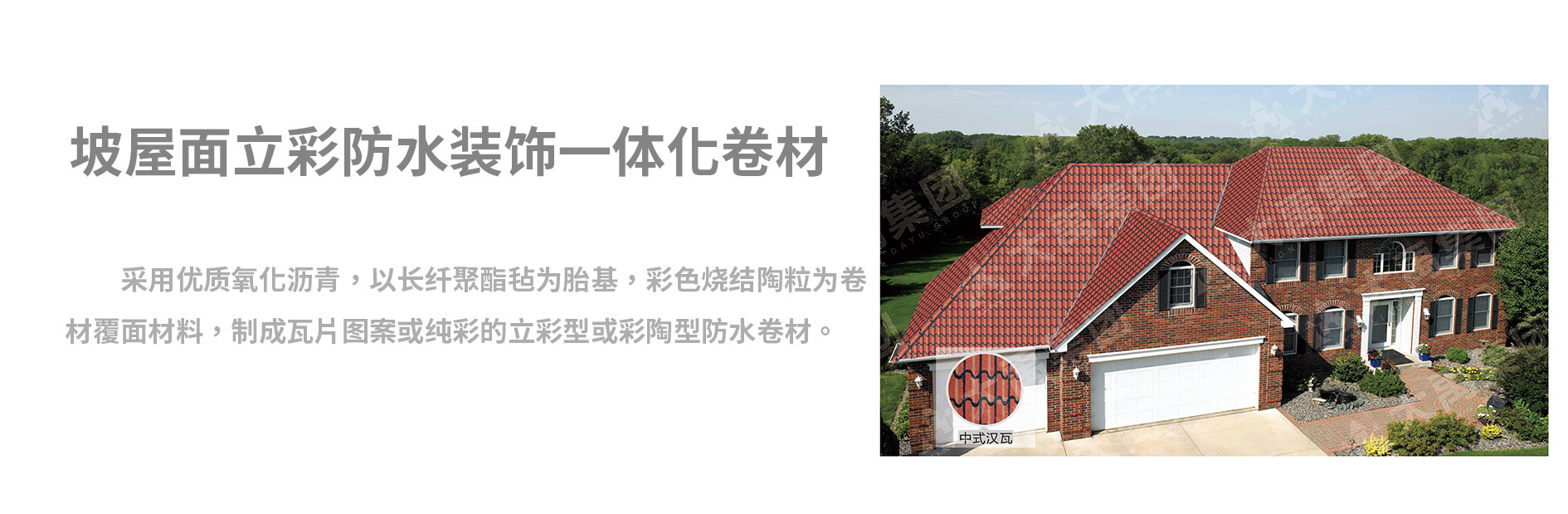

Product overview

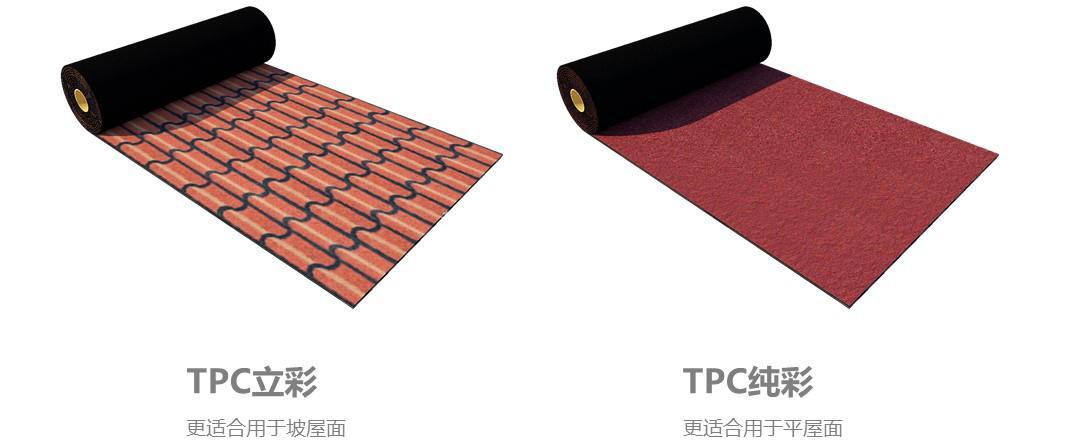

The use of high-quality oxidized asphalt, with long fiber polyester felt as the tire base, color sintered ceramsite as the coil cladding material, made of tile pattern or pure color of the standing color type or colored pottery type waterproof coil.

Product Features

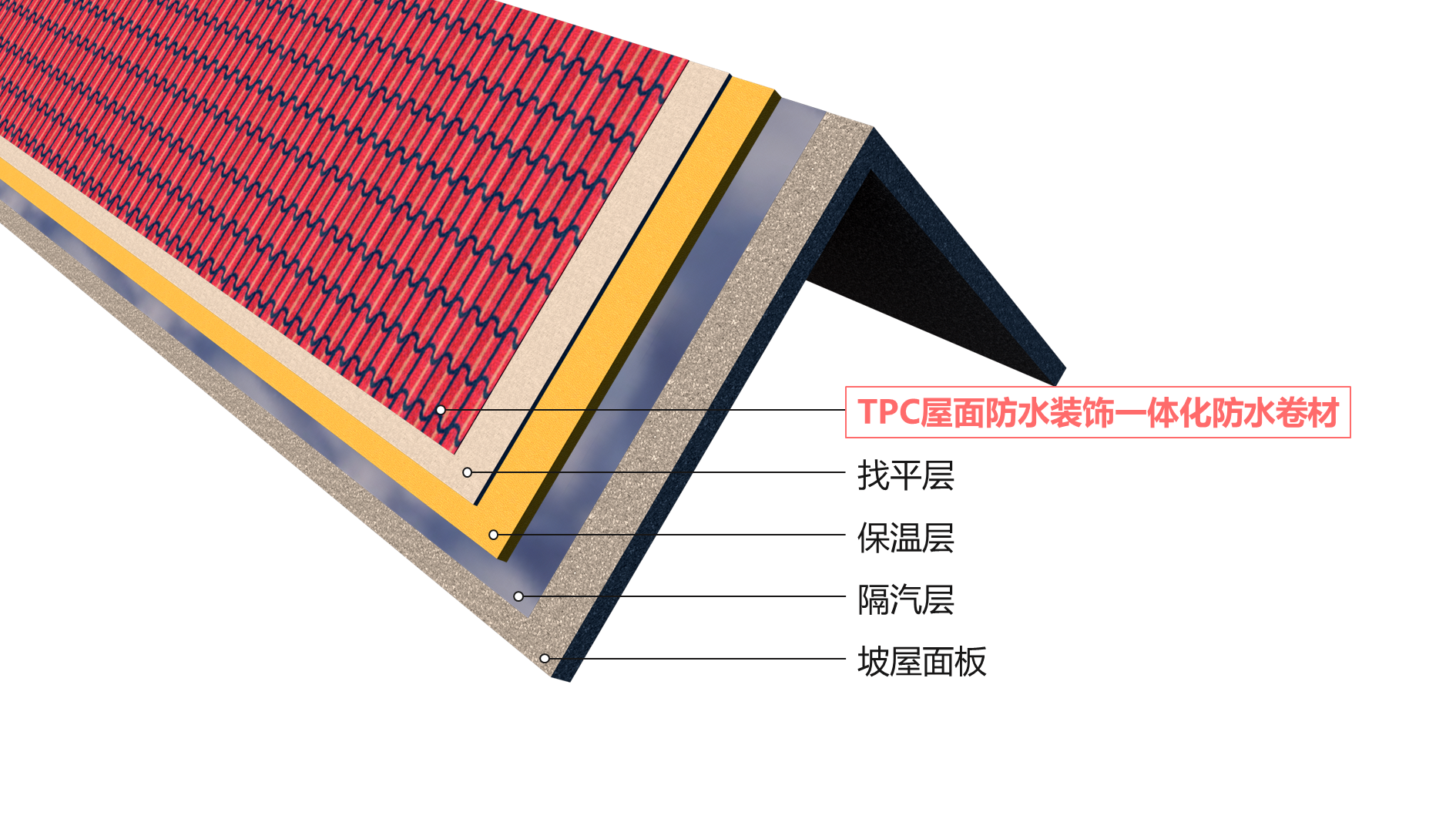

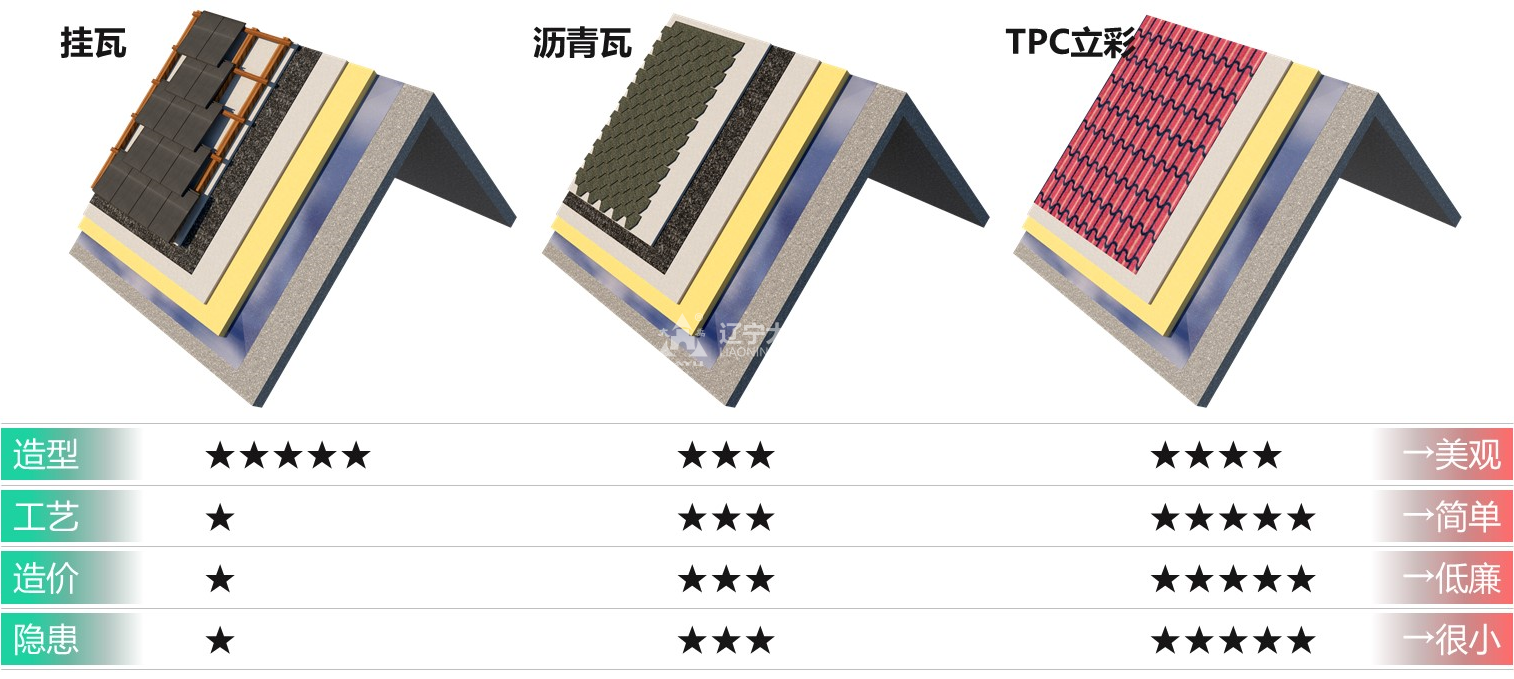

5 levels, simplify the complex, waterproof decoration in one step.

Good decorative effect, few structural levels, simple and reliable process, low cost

Good decorative effect, few structural levels, simple and reliable process, low cost

Regardless of wind, sun, rain, bright colors, durable.

Colored ceramsite cladding derived from sintered glaze at temperatures above 650°C, effectively resisting UV and high temperature damage

Tile design scheme is professional, with various schemes, bright colors and strong stereoscopic impression.

Richer colors than gray schist rolls, creating colorful roofing space

Specifications and models

|

Thickness |

3.0mm |

|

Width |

1000 mm |

|

Length |

10 m |

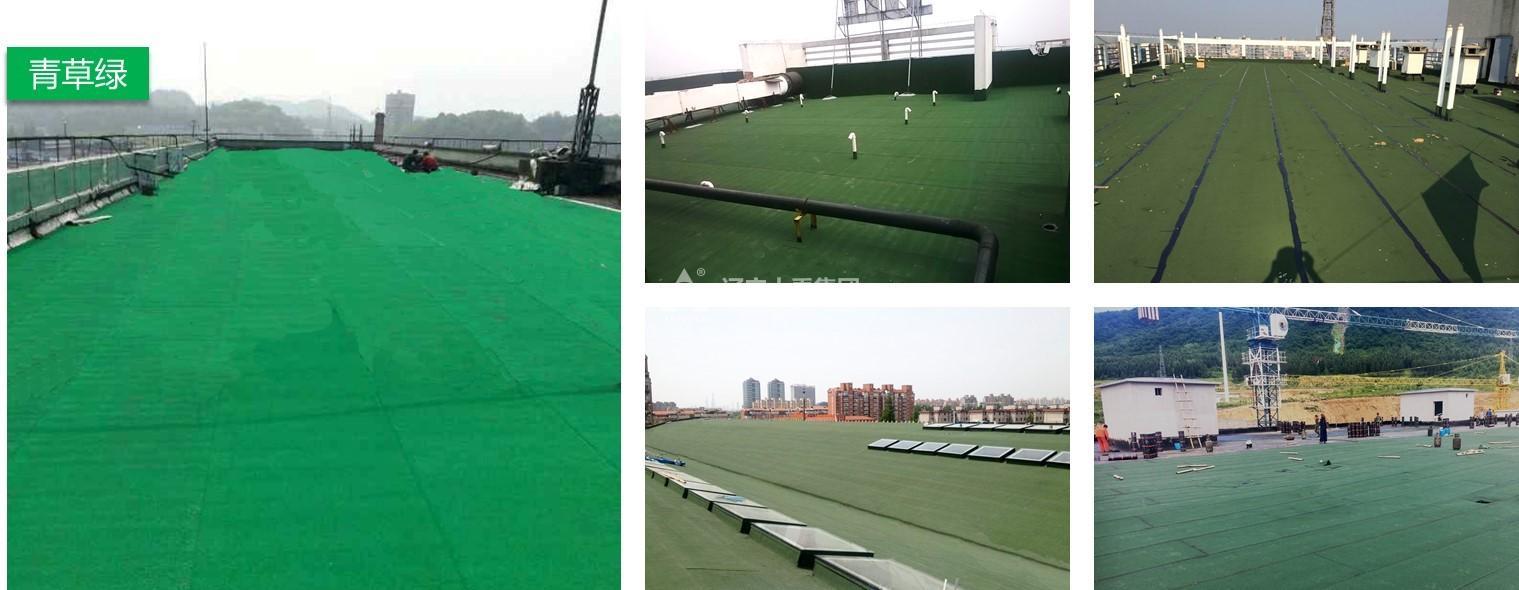

Scope of application

Applicable to the pursuit of roofing colorful effect, waterproof higher requirements of the roof waterproof decoration project.

New or renovated waterproofing works for sloping roofs and non-upper flat roofs.

Construction process

Basic requirements

The base is dry and solid, free of sediment and garbage, and free of empty drum, looseness and sand.

Coating base treatment agent

Spray or roll the matching base treatment agent to the base to ensure that the base treatment agent covers the base evenly and fully.

Trial laying coil

Spread the coiled material flat on the base surface, align the elastic line or the overlapping edge of adjacent coiled material, ensure the overlapping width, and rewind after static release of stress.

Hot melt paving

The burner bakes the lower surface and base surface of the coil, the colloid melts and rolls the coil in time, compacts and discharges steam while it is hot, so that the coil is fully close to the base surface,

Overlapping treatment

At the same time of hot-melt paving, press the lap edge with a pressure roller to extrude 5~8mm.Molten bitumen (considered reliable bonding).

performance index

Q/LDY 0004-2016 TPC Painted Pottery/Licai Covered Waterproofing Membrane

|

Pull force |

Elongation |

Tear strength |

Heat resistance |

low temperature flexibility |

|

500N/50mm |

≥30% |

200N |

90 ℃,2h without displacement, flowing or dripping |

No crack at -20 ℃ |

Previous Page