Product overview

Dayu®FB-SBS super modified asphalt waterproofing membrane is a hot-melt waterproofing membrane composed of tire base, super modified asphalt gum and surface material.

l fetal baseHigh quality filament polyester felt.

l Glial: European and American formula system, 100% pure raw material, construction performance, bonding performance, waterproof safety performance, service life are fully ahead of the national standard SBS coil.

l Surface material: Polyethylene film, fine sand or mineral granules.

Product Features

l The world's leading Italian Euroline company advanced production process preparation, product performance ahead of the regular SBS.

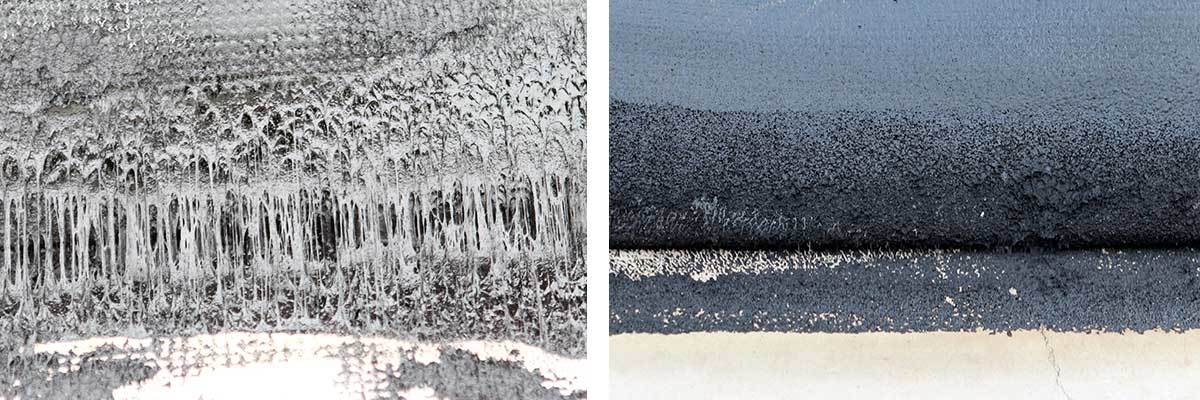

l The European and American formula system and 100% pure raw material have created a delicate and elastic colloid, which has a significant increase in bonding density with the base and a significant increase in waterproof performance.

l The peel strength (reflecting the bonding strength of the lap edge) is as high as 3.0N/mm, which is 2 to 3 times that of the regular SBS, which reduces the hidden danger of lap and improves the integrity of the waterproof layer.

l More excellent resistance to high and low temperature performance, low temperature not brittle crack, high temperature does not flow, good durability, roof waterproof service life of not less than 30 years, underground waterproof can be the same life with the building, long-term guarantee waterproof ability.

l High tensile strength, strong tear resistance, good dimensional stability and excellent mechanical properties.

l Only need to regular 50% of the heat of the coil, the coil can be melted, the construction efficiency is higher, and the waterproof sealing effect is more guaranteed.

l Mature hot melt method construction process, molten asphalt body lap, reliable bonding, lap firmly, suitable for all seasons.

l It can form a composite waterproof layer with other compatible coatings or coils to meet higher grade waterproof requirements.

FB-SBS super modified asphalt waterproofing membrane bonding effectregular bonding effect of SBS modified asphalt waterproofing membrane

Specification classification

|

Surface material |

Polyethylene film (PE)/S (fine sand)/M (mineral pellets) |

|

Thickness |

3.0 mm / 4.0 mm |

|

Width |

1000 mm |

|

Length |

7.5 m |

Scope of application

l It is suitable for industrial, civil, municipal and other construction projects, including administrative, residential, commercial, scientific research, medical, school, grain depot, pipe gallery and other buildings.

l It is suitable for underground engineering and roofing engineering with higher requirements for waterproof quality and construction life. Wherein, the surface material of mineral grains can be used for non-human roof exposed waterproof.

Construction process

L grass-roots requirements: solid, dry, free of sediment, laitance, no empty drum, loose, sand and other phenomena.

L interface treatment: uniform spray (roll) coating matching base treatment agent, improve the coil and the adhesion of the base.

L trial laying of coiled material: lay the coiled material flat on the base surface, align the elastic line or the overlapping edge of adjacent coiled material, adjust the overlapping width, let stand for a period of time to release the stress and then roll back.

L hot melt paving: bake the lower surface and base surface of the coil with a flame, push the roll paving coil forward in time after the colloid is melted, and compact and exhaust while it is hot to make the coil and the base closely bond.

L body lap joint: paving and pasting synchronous rolling lap joint edge to extrude 5~8mm molten asphalt (regarded as reliable lap joint).

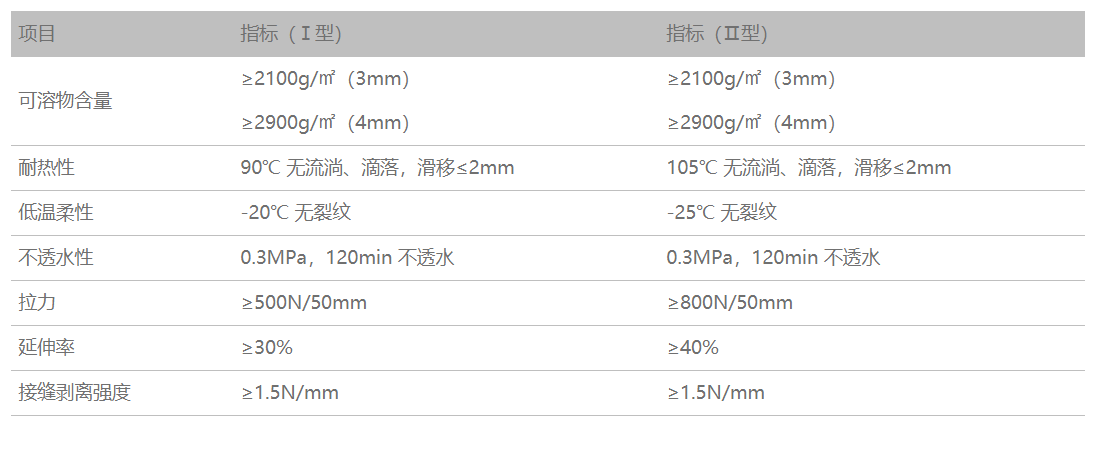

performance index

Products in accordance with the national standard "elastomer modified asphalt waterproofing membrane" GB18242-2008 manufacturing.

The material performance meets or exceeds the standard requirements, and the complete index is detailed in the standard.

List of basic physical performance indicators of coiled materials:

Previous Page